Real Time Indoor Air Quality Testing

INstascope

Know your Air, Instantly.

Technology for Instant Mold Inspection and Air Quality Assessment

What is InstaScope™?

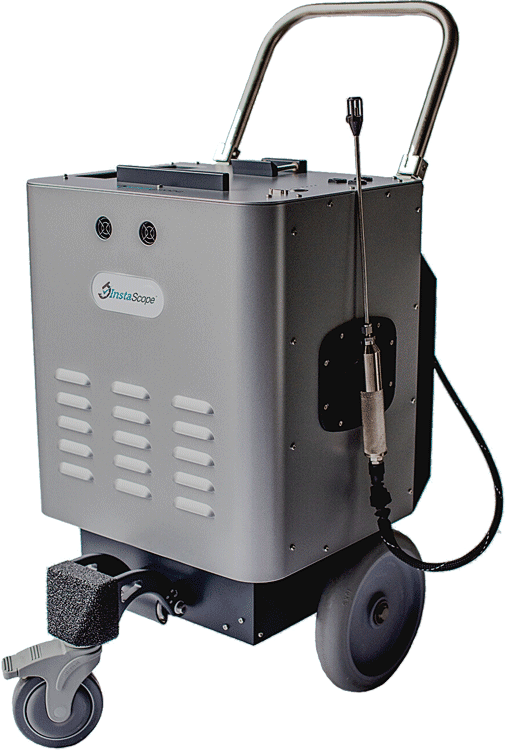

InstaScope is the most sophisticated technology used by service providers to assess indoor air quality through the detection of mold, bacteria/viruses, pollen and other airborne microbes. The technology performs a whole-area scan of every room for instant, objective, accurate results.

What does an inspection look like?

A typical session with the InstaScope can last around one hour or longer, depending on the size of the structure.

1. On the day of inspection, a service provider will arrive with the instrument and begin assessing the site based on square footage and number of rooms. The provider will measure room volume and take notes on each room so the instrument can accurately calculate samples.

2. Air quality assessment for an individual room takes approximately three minutes. This process is repeated for each room.

3. Once all scans are complete, a report is immediately generated. The reports can compare the air quality information for different rooms or other structures and be used to inform solutions that lower particle loading to the greatest extent.

How is Instascope different from other

Sampling Methods?

InstaScope is the only technology on the market that detects mold, bacteria/viruses, and pollen in real-time and generates reports for customers on-site.

There are several sampling tools on the market, but they risk static sampling that only sample a small portion of a room, as well as subjective analysis that can lead to inaccurate results. With InstaScope’s unlimited sampling capabilities, inspectors can perform a whole-area assessment of every room’s air quality.

This allows service providers to do more thorough investigations with informed solutions that will best optimize your indoor air quality. Traditional sampling methods have associated lab fees and can take several days for results to come back. InstaScope reports in real-time so customers can actually see mold spores spiking while a scan is being conducted.

How Does It Work?

AirByDesign moves the InstaScope through each room and “wands” the air to take samples. Particles enter through the InstaScope wand and flow into the instrument’s chamber.

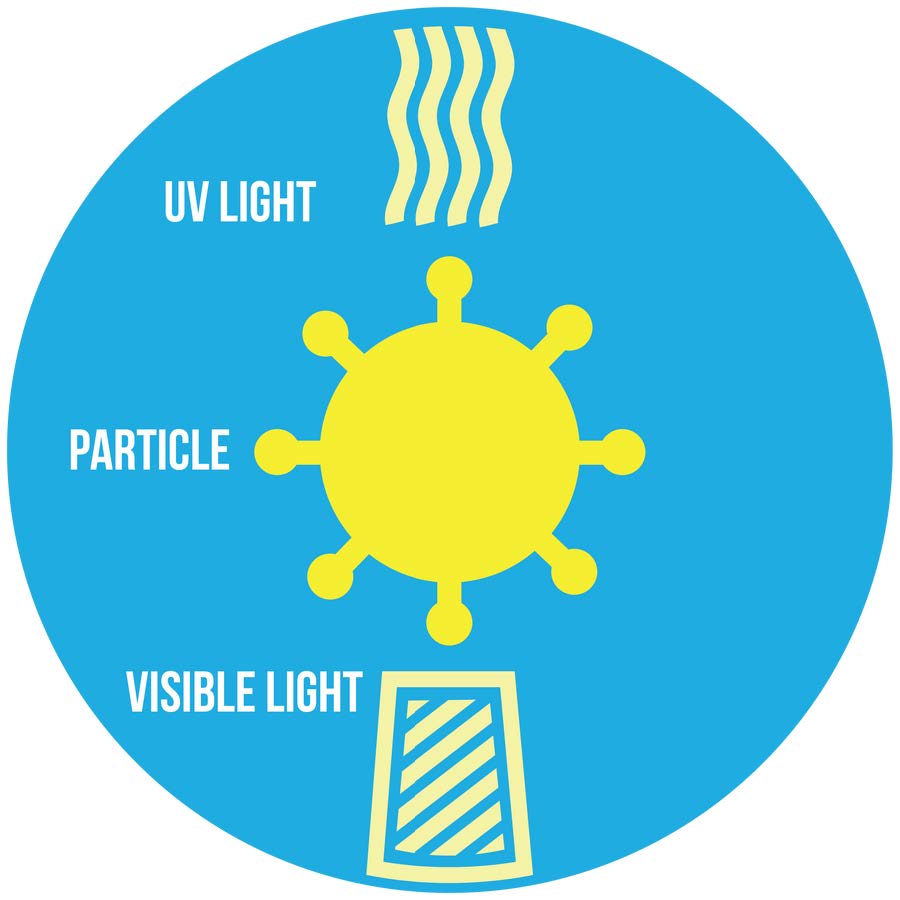

Inside the optical chamber, the mold particle is hit with a laser beam which determines its size. Based on the particles size, it will illuminate the particle in UV light.

The fluorescent light is then analyzed by the computer to determine specific size, color and color intensity of the particle. This is called biofluerensce and is what differentiates particles from one another.

Results of particle levels are displayed in real-time on the iPad and ready to review on-site.